LSHF :

LOW SMOKE HALOGEN-FREE CABLES

LOW SMOKE HALOGEN FREE CABLES

In certain application, cable under fire conditions have become a major concern. When conventional cables burn, they may emit smoke, halogen and toxic gases that may be harmful to both equipment and human beings.

After years of research and development, Prsymian Group is manufacturing and supply Low Smoke Halogen Free Cables which meets the severe requirement of cables under have the following characteristics

- Low Smoke : When the cable is on fire, it does not liberate large volume of dense black smoke. These cables when ignited will only produce a limited amount of smoke. This property helps to improve safety in areas where there are limited means to escape in the event of an emergency, or where large crowds are regularly in attendance.

- Halogen Free : When the cable is on fire, it does not emit any halogen gases. These are acidic and will attack equipment and human beings. The property help to protect computer, electronic/communication equipment and reduces thee toxicity of thee gases emitted from the fire. This reduces the risk of personal engaged in vital operations being incapacitatded and the safe escape of people in an emergency

With the superior fire performance, these range of cables are recommended for use in the following areas :

- Underground tunnels, lifs, power stations

- Mass Rapid Transit System

- Airports

- Large building/Multi Story Building

- Critical area of an installations e.g. escape route of an installation

- Oil Platforms/Ships

- Areas where masses of people gather and limited means in the event of a fire

- Military installations/equipment / machines

- Critical circuits that must continue to operate in case of a fire. e.g. Fire alarms, emergency lifts, pumps circuits etc.

CHARACTERISTICS OF LOW SMOKE HALOGEN FREE CABLES

Applicable test methods / standards for Low Smoke Halogen Free Property Performance in fire Tests

|

Fire Propagation

|

|

IEC 60332 PART 3

|

(International)

|

|

BS 4066 PART 3

|

(UK)

|

|

CEI 20-22

|

(Italy)

|

|

VDE 804C

|

(Germany)

|

|

NF C 32-070 CAT.C1

|

(France)

|

|

IEEE 383

|

(USA)

|

|

UL 1581

|

(USA)

|

|

UL 1666

|

(USA)

|

|

FT4

|

(Canada)

|

|

AS 1660.5.1

|

(Australia)

|

|

Cables jacketed with polyethylene or certain type of PVC compounds have the potential to spread or propagate a fire along a cable run. Many international bodies have devised tests designed to assess this property. LSHF Cables are flame retardant and hence both hard to ignite and only burn with difficulty. Cables jacketed with LSHD compound have consistently been found to comply with most of these needs.

|

|

Acid Gas

|

|

IEC 60754 PART 1

|

(International)

|

|

IEC 60754 PART 2

|

(International)

|

|

CEI 20-37 PART 1

|

(Italy)

|

|

VDE 0472 Part 813

|

(Germany)

|

|

NF C 20453

|

(France)

|

|

AS 1660.5.4

|

(Australia)

|

|

Many flame retardant compounds are based on halogen containing chemicals. Halogen can be present as part of the polymer e.g. PVC or may be a component of a flame retardant additive. When burnt, these materials liberate acidic gases such as hydrochloric gas which, when in contact with electrical or electronic component, can cause very expensive corrosion damage. The cost of thee communication equipment. LSHF Cables are designed not to release acidic gases.

|

|

Smoke

|

|

IEC 60034

|

(International)

|

|

UITP E4

|

(International)

|

|

BS 7622

|

(UK)

|

|

UTE C 20-452

|

(France)

|

|

CEI 20-37 Part 3 METHOD

|

(Italy)

|

|

ASTM E662

|

(USA)

|

|

AS 1660.5.4

|

(Australia)

|

|

Several materials used in the manufacture of electric wire and cables can liberate large volumes of dense black smoke when ignited. LSHF Cables however, are designed to produce only limited amounts of smoke when they are expose to fire. This property help to impover safety in areas where there are limited means of escape in the event of an emergency, or where large crowds are regularly in attendance.

|

|

Toxicity

|

|

Naval Engineering Standard 713

|

(UK)

|

|

CEI 20-37 Part 2

|

(Italy)

|

|

NF C 20-454

|

(France)

|

|

The evolution of toxic fumes from burning materials has been of concern to a variety of industries. In the case of electric wire and cables, toxic gases are of particular importance where they may hamper the safe escape of people in an emergency, or incapacitate personal engaged in vital operation. LSHF Cables do not liberate the highly toxic species generated by some other cable material as in the case of LSHF Cables the main products of combustion are water and carbon dioxide. LSHF Cables comply with most military toxic gas evolution specifications.

|

CONSTRUCTION OF CABLE

|

Construction

|

|

|

1.Conductor

|

Stranded annealed copper

|

|

2.Insulation

|

|

|

3.Shield*

|

Aluminium foil with tinned copper drain wire

|

|

4.Filler*

|

LSHF filler or polypropylene split yam

|

|

5.Binder Tape*

|

Polyester tape

|

|

6.Bedding

|

Low smoke halogen free (LSHF) compound

|

|

7.Amour*/#

|

Galvanised steel wire (aluminium or copper wire for single core)

|

|

8.Sheath

|

Low smoke halogen free (LSHF) compound

|

|

No. of cores

|

Identification of cores

|

|

Option 1

|

Option 2

|

|

1

|

Natural

|

Other color on request

|

|

2

|

Brown, blue

|

Red, Black

|

|

3

|

Brown, Black, Grey

|

Red, Yellow, Blue

|

|

4

|

Brown, Black, Grey, Blue

|

Red, Yellow, Blue, Black

|

|

5

|

Brown, Black, Grey, Blue, Green/Yellow

|

Red, Yellow, Blue, Black, Green/Yellow

|

|

6 and above

|

Black with white numbering (Other on request)

|

|

Pairs

|

Black with white numbering

|

Note: Special construction and design to customers’ specification can be upon request

Applicable Standards

|

IEC 60502-1

|

Extruded solid dielectric insulated power cable for rated voltage of 1 kV up to 30 kV

|

|

IEC 60228/BS 6360

|

Conductor of insulated cables

|

|

IEC 60754-1/BS 6425-2

|

Test on gases evolved during combustion of electric cables- Determination of the amount of halogen acid gases

|

|

IEC 60754-2/BS 6426-2

|

Test on gase evolved during combustion of electric cables- Determination of degree of acidity of acidity of gases evolved by measuring pH and conductivity

|

|

IEC 61034/BS 7622

|

Measurement of smoke density of cables burning under defined conditions

|

|

BS 6724

|

Armoured cables for electricity supply having thermosetting insulation with low emission of smoke and corrosive gase when affected by fire

|

|

BS 7211

|

Thermosetting insulated cables (non-armored) For electric power and lighting with low emission of smoke and corrosive gases when affected by fire

|

|

BS 7846

|

600/1000V armoured fire-resistant electric cables having low emission of smoke and corrosive gases when affected by fire

|

|

IEC 60332-3

|

Test of the fire behavior on bunched cables (Reduced flame propagation)

|

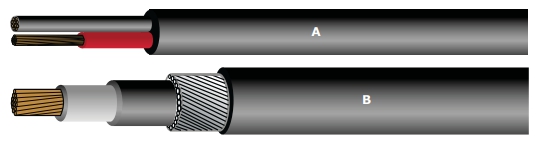

TABLE OF CONSTRUCTION

600/1000V, Unarmoured and Armoured LSHF Cables

|

core

|

(A)

Unarmoured cables

|

(B)

Armoured Cables

|

|

Nominal area of conductor

|

Insulation,

non-sheathed

|

Insulation,

sheathed

|

Insulation,

sheathed

|

|

Insulation Thickness

|

Approx. diameter overall

|

Approx. weight

|

Insulation Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

Bedding Thickness

|

Armour wire Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

|

mm²

|

mm

|

mm

|

Kg/km

|

mm

|

Mm

|

mm

|

Kg/km

|

mm

|

mm

|

mm

|

mm

|

Kg/km

|

|

Single core

|

1.5

|

0.7

|

3.9

|

32

|

0.7

|

1.4

|

6.4

|

55

|

-

|

-

|

-

|

-

|

-

|

|

2.5

|

0.8

|

4.6

|

43

|

0.7

|

1.4

|

6.8

|

70

|

-

|

-

|

-

|

-

|

-

|

|

4

|

0.8

|

5.1

|

55

|

0.7

|

1.4

|

7.4

|

90

|

-

|

-

|

-

|

-

|

-

|

|

6

|

0.8

|

5.6

|

85

|

0.7

|

1.4

|

7.9

|

110

|

-

|

-

|

-

|

-

|

-

|

|

10

|

1.0

|

7.1

|

146

|

0.7

|

1.4

|

8.9

|

160

|

-

|

-

|

-

|

-

|

-

|

|

16

|

1.0

|

8.1

|

198

|

0.7

|

1.4

|

9.9

|

220

|

-

|

-

|

-

|

-

|

-

|

|

25

|

1.2

|

9.8

|

320

|

0.9

|

1.4

|

12.2

|

330

|

-

|

-

|

-

|

-

|

-

|

|

35

|

1.2

|

10.9

|

410

|

0.9

|

1.4

|

13.5

|

430

|

-

|

-

|

-

|

-

|

-

|

|

50

|

1.4

|

13.4

|

549

|

1.0

|

1.4

|

15.0

|

560

|

1.0

|

1.25

|

1.8

|

19.6

|

800

|

|

70

|

1.4

|

15.2

|

770

|

1.1

|

1.4

|

17.0

|

770

|

1.0

|

1.25

|

1.8

|

22.5

|

1000

|

|

95

|

1.6

|

17.6

|

1140

|

1.1

|

1.5

|

19.0

|

1040

|

1.0

|

1.25

|

1.8

|

24.0

|

1400

|

|

120

|

1.6

|

19.3

|

1425

|

1.2

|

1.5

|

20.8

|

1290

|

1.0

|

1.60

|

1.8

|

27.0

|

1700

|

|

150

|

1.8

|

21.3

|

1720

|

1.4

|

1.6

|

23.0

|

1580

|

1.0

|

1.60

|

1.8

|

29.0

|

2000

|

|

185

|

2.0

|

23.7

|

2155

|

1.6

|

1.6

|

25.3

|

1950

|

1.0

|

1.60

|

1.9

|

31.3

|

2400

|

|

240

|

2.2

|

26.8

|

2900

|

1.7

|

1.7

|

28.3

|

2530

|

1.0

|

1.60

|

2.0

|

35.0

|

3300

|

|

300

|

2.4

|

29.7

|

3540

|

1.8

|

1.8

|

31.0

|

3140

|

1.0

|

1.60

|

2.1

|

37.0

|

3800

|

|

400

|

2.6

|

33.3

|

4410

|

2.0

|

2.9

|

34.7

|

3970

|

1.2

|

2.00

|

2.3

|

42.0

|

4800

|

|

500

|

2.8

|

37.2

|

5660

|

2.2

|

2.0

|

38.5

|

4970

|

1.2

|

2.00

|

2.4

|

46.0

|

5900

|

|

630

|

2.8

|

41.3

|

7140

|

2.4

|

2.2

|

43.5

|

6400

|

1.2

|

2.00

|

2.5

|

51.0

|

7400

|

|

800

|

-

|

-

|

-

|

2.6

|

2.3

|

48.0

|

8000

|

1.4

|

2.00

|

2.8

|

57.0

|

9400

|

|

1000

|

-

|

-

|

-

|

2.8

|

2.4

|

53.2

|

10200

|

1.4

|

2.00

|

2.9

|

62.0

|

11000

|

|

Two cores

|

1.5

|

-

|

-

|

-

|

0.7

|

1.8

|

10.4

|

150

|

1.0

|

0.90

|

1.8

|

15.0

|

400

|

|

2.5

|

-

|

-

|

-

|

0.7

|

1.8

|

11.2

|

180

|

1.0

|

0.90

|

1.8

|

16.0

|

450

|

|

4

|

-

|

-

|

-

|

0.7

|

1.8

|

12.3

|

240

|

1.0

|

0.90

|

1.8

|

17.0

|

530

|

|

6

|

-

|

-

|

-

|

0.7

|

1.8

|

13.5

|

300

|

1.0

|

0.90

|

1.8

|

18.0

|

620

|

|

10

|

-

|

-

|

-

|

0.7

|

1.8

|

15.7

|

420

|

1.0

|

1.25

|

1.8

|

20.0

|

900

|

|

16

|

-

|

-

|

-

|

0.7

|

1.8

|

17.8

|

590

|

1.0

|

1.25

|

1.8

|

22.0

|

1050

|

|

25

|

-

|

-

|

-

|

0.9

|

1.8

|

21.2

|

860

|

1.0

|

1.60

|

1.8

|

26.5

|

1600

|

|

35

|

-

|

-

|

-

|

0.9

|

1.8

|

23.7

|

1120

|

1.0

|

1.60

|

1.9

|

29.0

|

1964

|

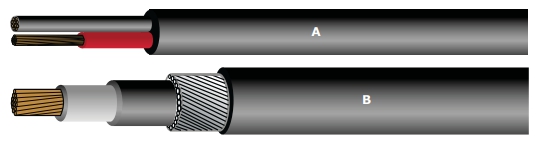

A Unarmoured cables

B Armoured Cables

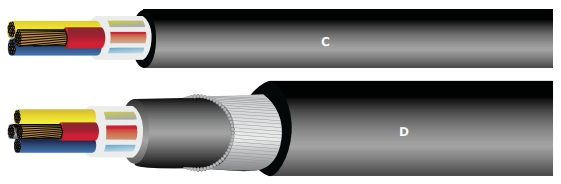

600/1000V, Unarmoured and Armoured LSHF Cables

Table 2

|

|

(C) Unarmoured cables

|

(D) Armoured Cables

|

|

Nominal area of conductor

|

Insulation Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

Bedding Thickness

|

Armour wire Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

|

mm²

|

mm

|

mm

|

mm

|

Kg/km

|

mm

|

mm

|

mm

|

mm

|

Kg/km

|

|

Three cores

|

1.5

|

0.7

|

1.8

|

10.0

|

170

|

1.0

|

0.90

|

1.8

|

14.5

|

400

|

|

2.5

|

0.7

|

1.8

|

11.0

|

215

|

1.0

|

0.90

|

1.8

|

15.4

|

470

|

|

4

|

0.7

|

1.8

|

12.1

|

280

|

1.0

|

0.90

|

1.8

|

16.5

|

560

|

|

6

|

0.7

|

1.8

|

13.3

|

360

|

1.0

|

1.25

|

1.8

|

16.5

|

770

|

|

10

|

0.7

|

1.8

|

15.3

|

510

|

1.0

|

1.25

|

1.8

|

20.5

|

1000

|

|

16

|

0.7

|

1.8

|

17.6

|

740

|

1.0

|

1.60

|

1.8

|

23.4

|

1400

|

|

25

|

0.9

|

1.8

|

21.3

|

1100

|

1.0

|

1.60

|

1.8

|

28.0

|

1900

|

|

35

|

0.9

|

1.8

|

24.0

|

1400

|

1.0

|

1.60

|

1.9

|

30.3

|

2400

|

|

50

|

1.0

|

1.8

|

27.1

|

1900

|

1.0

|

1.60

|

2.1

|

34.5

|

3140

|

|

70

|

1.1

|

2.0

|

32.0

|

2600

|

1.2

|

2.00

|

2.2

|

39.5

|

4150

|

|

95

|

1.1

|

2.1

|

37.0

|

3500

|

1.2

|

2.00

|

2.4

|

43.9

|

5400

|

|

120

|

1.2

|

2.3

|

42.0

|

4400

|

1.4

|

2.50

|

2.6

|

49.6

|

6830

|

|

150

|

1.4

|

2.4

|

45.0

|

5500

|

1.4

|

2.50

|

2.7

|

54.1

|

8080

|

|

185

|

1.6

|

2.6

|

50.3

|

6800

|

1.4

|

2.50

|

2.9

|

59.4

|

9720

|

|

240

|

1.7

|

2.8

|

56.8

|

8800

|

1.6

|

2.50

|

3.1

|

66.3

|

12000

|

|

300

|

1.8

|

3.0

|

62.8

|

10900

|

1.6

|

3.15

|

3.3

|

74.0

|

15500

|

|

Four cores

|

1.5

|

0.7

|

1.8

|

10.8

|

180

|

1.0

|

0.90

|

1.8

|

15.3

|

450

|

|

2.5

|

0.7

|

1.8

|

11.8

|

240

|

1.0

|

0.90

|

1.8

|

16.3

|

530

|

|

4

|

0.7

|

1.8

|

13.1

|

320

|

1.0

|

1.25

|

1.8

|

18.3

|

740

|

|

6

|

0.7

|

1.8

|

14.7

|

430

|

1.0

|

1.25

|

1.8

|

19.6

|

900

|

|

10

|

0.7

|

1.8

|

16.7

|

629

|

1.0

|

1.25

|

1.8

|

21.9

|

1150

|

|

16

|

0.7

|

1.8

|

19.3

|

870

|

1.0

|

1.60

|

1.8

|

25.3

|

1620

|

|

25

|

0.9

|

1.8

|

23.4

|

1330

|

1.0

|

1.60

|

1.9

|

30.0

|

2260

|

|

35

|

0.9

|

1.8

|

26.4

|

1770

|

1.0

|

1.60

|

2.0

|

33.9

|

3060

|

|

50

|

1.0

|

1.8

|

30.0

|

2330

|

1.2

|

2.00

|

2.2

|

37.9

|

3860

|

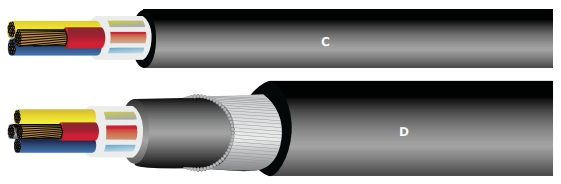

C Unarmoured cables

D Armoured Cables

* Multicore unarmoured and armoured fire resistant cables are available upon request

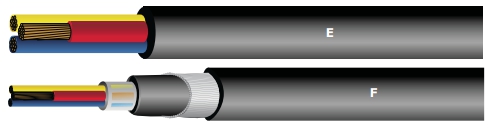

500V, Unarmoured and Armoured LSHF Cables

Table 3

|

|

Unarmoured /cable

|

Armoured /cable

|

|

Nominal area of conductor

|

No.& Diameter of wires

|

Insulation Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

Bedding Thickness

|

Armour wire Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

|

mm²

|

No./mm

|

mm

|

mm

|

mm

|

Kg/km

|

mm

|

mm

|

mm

|

mm

|

Kg/km

|

|

Single core

|

0.75

|

7/0.37

|

0.55

|

0.5

|

4.1

|

22

|

0.5

|

0.9

|

1.4

|

8.9

|

155

|

|

1

|

7/0.44

|

0.55

|

0.5

|

4.3

|

26

|

0.5

|

0.9

|

1.4

|

9.1

|

165

|

|

1.5

|

7/0.53

|

0.55

|

0.5

|

4.6

|

32

|

0.5

|

0.9

|

1.4

|

9.4

|

180

|

|

2.5

|

7/0.67

|

0.55

|

0.5

|

5.0

|

43

|

0.5

|

0.9

|

1.4

|

9.8

|

200

|

|

4

|

7/0.85

|

0.55

|

0.5

|

5.6

|

60

|

0.5

|

0.9

|

1.4

|

10.4

|

240

|

|

Two cores

|

0.75

|

7/0.37

|

0.55

|

0.5

|

7.0

|

64

|

0.5

|

0.9

|

1.4

|

11.8

|

285

|

|

1

|

7/0.44

|

0.55

|

0.5

|

7.4

|

74

|

0.5

|

0.9

|

1.4

|

12.2

|

310

|

|

1.5

|

7/0.53

|

0.55

|

0.5

|

8.0

|

92

|

0.5

|

0.9

|

1.4

|

12.8

|

345

|

|

2.5

|

7/0.67

|

0.55

|

0.5

|

8.8

|

120

|

0.5

|

0.9

|

1.4

|

13.6

|

400

|

|

4

|

7/0.85

|

0.55

|

0.5

|

9.9

|

165

|

0.5

|

0.9

|

1.4

|

14.7

|

475

|

|

Three cores

|

0.75

|

7/0.37

|

0.55

|

0.5

|

7.5

|

75

|

0.5

|

0.9

|

1.4

|

12.3

|

310

|

|

1

|

7/0.44

|

0.55

|

0.5

|

7.9

|

88

|

0.5

|

0.9

|

1.4

|

12.7

|

355

|

|

1.5

|

7/0.53

|

0.55

|

0.5

|

8.5

|

110

|

0.5

|

0.9

|

1.4

|

13.3

|

375

|

|

2.5

|

7/0.67

|

0.55

|

0.5

|

9.4

|

150

|

0.5

|

0.9

|

1.4

|

14.2

|

445

|

|

4

|

7/0.85

|

0.55

|

0.5

|

10.6

|

205

|

0.5

|

0.9

|

1.4

|

15.4

|

535

|

|

Four cores

|

0.75

|

7/0.37

|

0.55

|

0.5

|

8.3

|

90

|

0.5

|

0.9

|

1.4

|

13.1

|

360

|

|

1

|

7/0.44

|

0.55

|

0.5

|

8.7

|

105

|

0.5

|

0.9

|

1.4

|

13.5

|

380

|

|

1.5

|

7/0.53

|

0.55

|

0.5

|

9.4

|

135

|

0.5

|

0.9

|

1.4

|

14.2

|

430

|

|

2.5

|

7/0.67

|

0.55

|

0.5

|

10.4

|

180

|

0.5

|

0.9

|

1.4

|

15.2

|

500

|

|

4

|

7/0.85

|

0.55

|

0.5

|

11.7

|

255

|

0.5

|

0.9

|

1.4

|

16.7

|

620

|

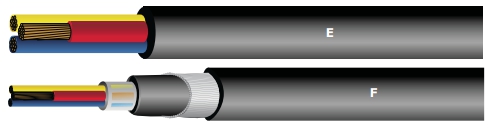

E Unarmoured fire resistant cables

F Armoured fire resistant cables

* Multicore unarmoured and armoured fire resistant cables are available upon request

500V, Unarmoured and Armoured LSHF Cables

Table 4

|

|

Unarmoured /cable

|

Armoured /cable

|

|

Nominal area of conductor

|

No.& Diameter of wires

|

Insulation Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

Bedding Thickness

|

Armour wire Thickness

|

Sheath Thickness

|

Approx. diameter overall

|

Approx. weight

|

|

mm²

|

No./mm

|

mm

|

mm

|

mm

|

Kg/km

|

mm

|

mm

|

mm

|

mm

|

Kg/km

|

|

Single core

|

0.75

|

7/0.37

|

0.5

|

0.8

|

7.9

|

65

|

0.8

|

0.9

|

1.4

|

12.7

|

300

|

|

1

|

7/0.43

|

0.6

|

0.8

|

8.5

|

75

|

0.8

|

0.9

|

1.4

|

13.3

|

340

|

|

1.5

|

7/0.53

|

0.5

|

0.8

|

9.1

|

90

|

0.8

|

0.9

|

1.4

|

13.9

|

370

|

|

2.5

|

7/0.67

|

0.6

|

0.8

|

9.9

|

110

|

0.8

|

0.9

|

1.4

|

14.7

|

420

|

|

Two cores

|

0.75

|

7/0.37

|

0.5

|

0.8

|

10.0

|

100

|

0.8

|

0.9

|

1.4

|

14.8

|

410

|

|

1

|

7/0.43

|

0.6

|

0.9

|

11.0

|

125

|

0.9

|

0.9

|

1.4

|

15.8

|

460

|

|

1.5

|

7/0.53

|

0.6

|

0.9

|

11.8

|

150

|

0.9

|

0.9

|

1.5

|

16.8

|

520

|

|

2.5

|

7/0.67

|

0.6

|

1.0

|

13.1

|

205

|

1.0

|

0.9

|

1.5

|

18.1

|

605

|

|

Three cores

|

0.75

|

7/0.37

|

0.5

|

1.0

|

12.2

|

145

|

1.0

|

0.9

|

1.5

|

17.2

|

565

|

|

1

|

7/0.43

|

0.6

|

1.0

|

13.1

|

170

|

1.0

|

0.9

|

1.5

|

18.1

|

600

|

|

1.5

|

7/0.53

|

0.6

|

1.0

|

14.1

|

215

|

1.0

|

0.9

|

1.6

|

19.3

|

655

|

|

2.5

|

7/0.67

|

0.6

|

1.1

|

15.7

|

290

|

1.1

|

1.25

|

1.6

|

21.6

|

920

|

|

Four cores

|

0.75

|

7/0.37

|

0.5

|

1.0

|

13.7

|

180

|

1.0

|

0.9

|

1.5

|

18.7

|

600

|

|

1

|

7/0.43

|

0.6

|

1.0

|

14.7

|

215

|

1.0

|

1.25

|

1.6

|

20.6

|

820

|

|

1.5

|

7/0.53

|

0.6

|

1.1

|

16.1

|

280

|

1.1

|

1.25

|

1.6

|

22.0

|

920

|

|

2.5

|

7/0.67

|

0.6

|

1.1

|

17.7

|

370

|

1.1

|

1.25

|

1.6

|

23.8

|

1090

|

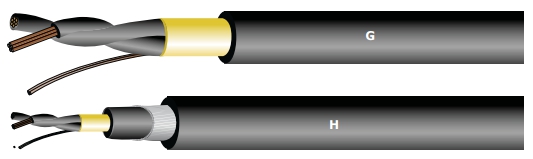

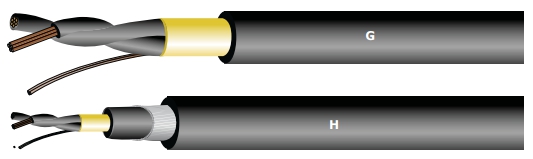

G Unarmoured fire resistant cables

H Armoured fire resistant cables

* Multi-pairs unarmoured and armoured shielded fire resistant cables are available upon request

ข้อมูลสายทนไฟ FIRE RESISTANT CABLE (FRC)

ข้อมูลสายทนไฟ FIRE RESISTANT CABLE (FRC)  คุณสมบัติและมาตรฐานของสายทนไฟ FRC สายต้านทานการลามไฟ FD และ สายไม่ปล่อยควันและก๊าซกรด LSHF

คุณสมบัติและมาตรฐานของสายทนไฟ FRC สายต้านทานการลามไฟ FD และ สายไม่ปล่อยควันและก๊าซกรด LSHF  สาย LSF (LSHF, LSZH)

สาย LSF (LSHF, LSZH)  FRC MAX-FOH MCI DRAKA & PRYSMIAN

FRC MAX-FOH MCI DRAKA & PRYSMIAN  สายทนไฟ Fire resistant cable

สายทนไฟ Fire resistant cable