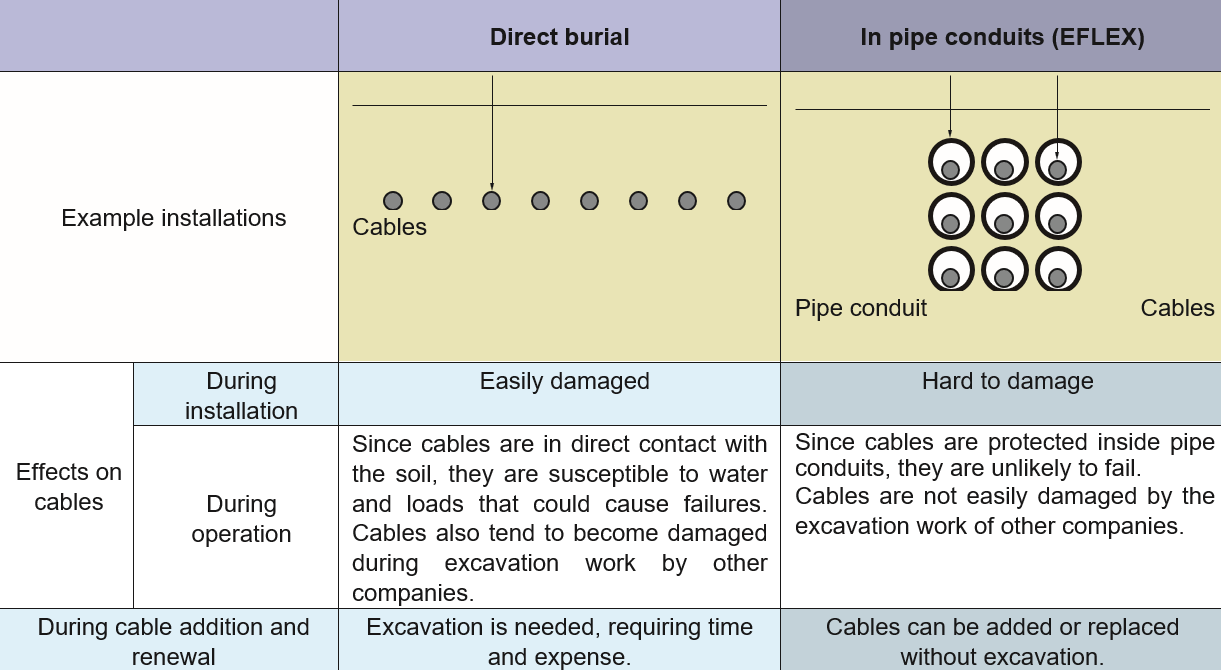

A track record of more than 40 years in Japan:

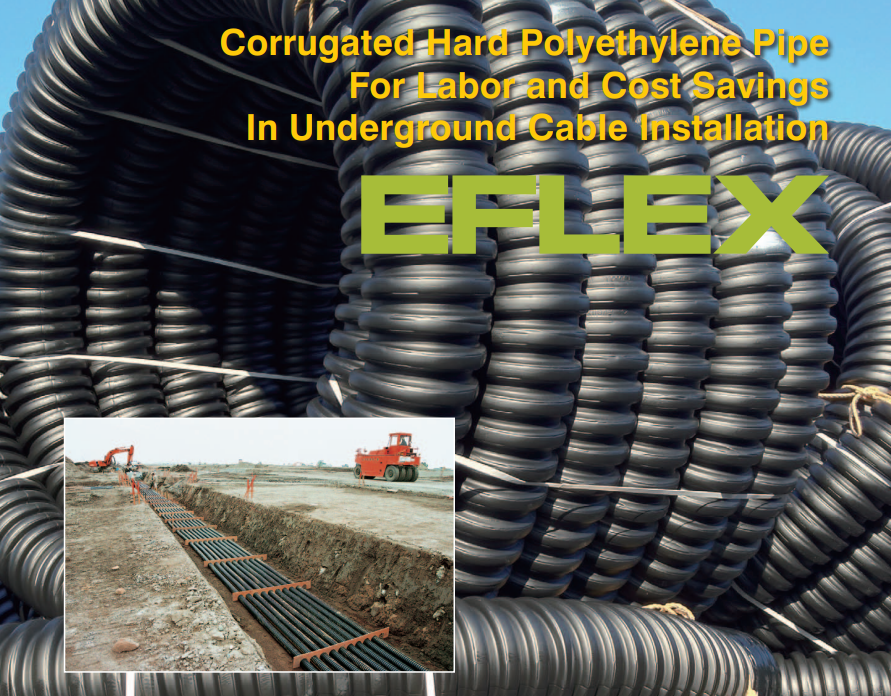

EFLEX, underground electrical cable protective pipe

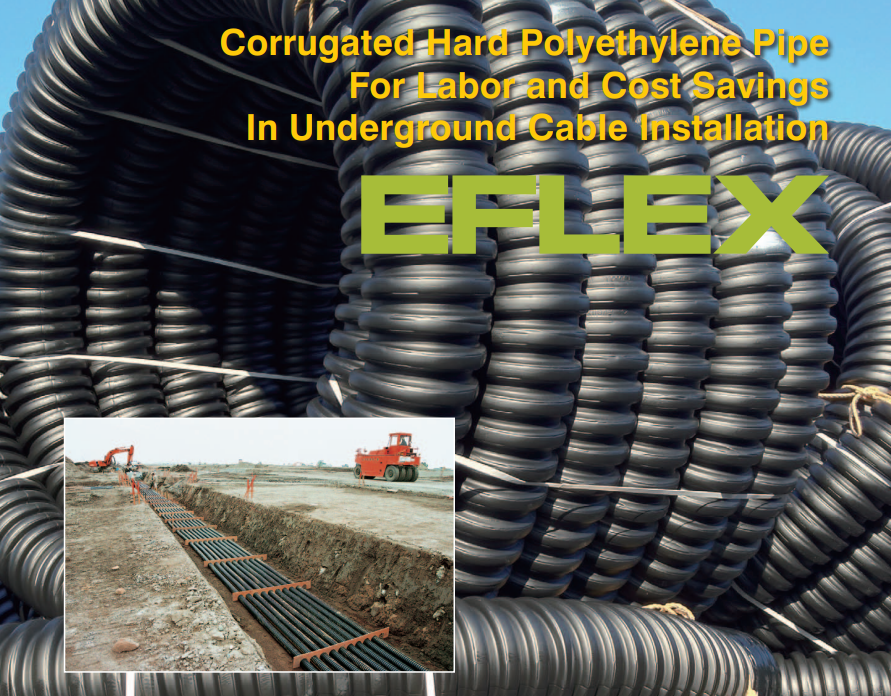

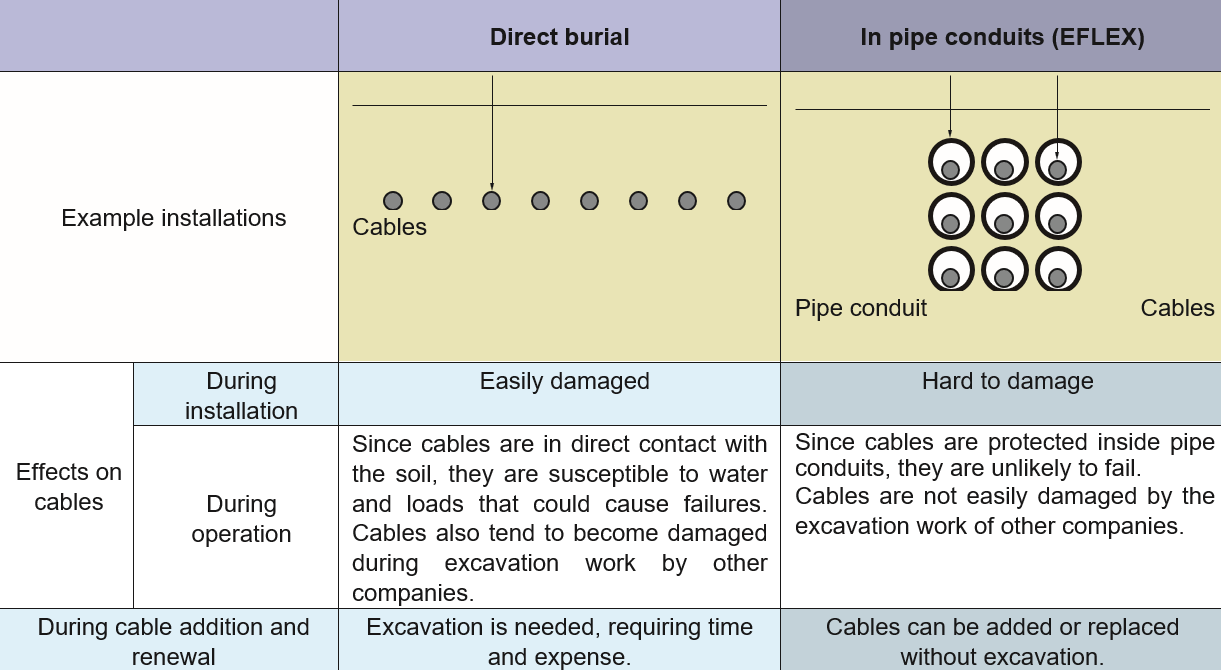

🔸Comparing cables buried directly with cables laid inside pipe conduits (EFLEX) laid inside pipe conduits (EFLEX)

🔸 Feratures of EFLEX

.png)

EFLEX boasts the product lineup from ø30 to ø200

| |

Underground Cable Conduit EFLEX |

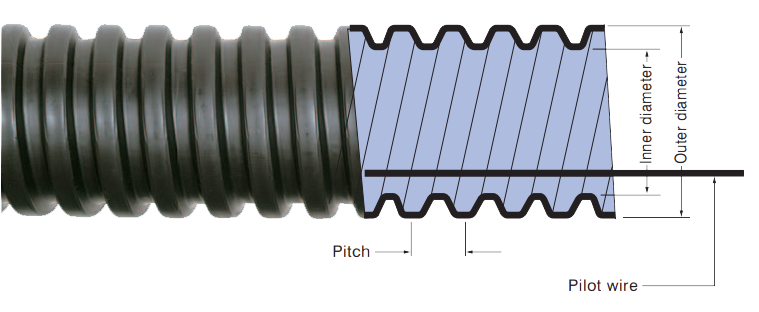

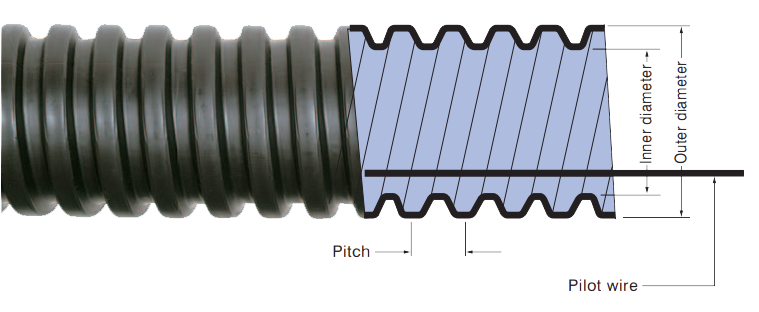

- The standard dimensions of EFLEX are as shown in the table below. A pilot wire is inserted inside EFLEX during production. It is connected with the cable pilot wire to pull the cable into the pipe. EFLEX is, as a rule, shipped from the factory, wound in a coil. A pilot wire has an allowable tensile strength of 50 kg.

|

|

FP

Standard dimensions table

Product

No. |

Outer

diameter (approx.

in mm) |

Inner

diameter (approx.

in mm) |

Pitch (approx.

in mm) |

Reference weight

(approx.

in kg/m) |

Standard

length

of

product bundle

(m) |

Standard dimensions

of product

bundle

Outer

diameter x weight

(approx. in m) |

| FP-30 |

40 |

30 |

10 |

0.2 |

300 |

1.2 x 0.5 |

| FP-40 |

54 |

42 |

13 |

0.3 |

200 |

1.5 x 0.65 |

| FP-50 |

65 |

50 |

17 |

0.4 |

200 |

1.6 x 0.7 |

| FP-65 |

85 |

66 |

21 |

0.6 |

100 |

1.6 x 0.65 |

| FP-80 |

102 |

80 |

25 |

0.7 |

100 |

1.7 x 0.7 |

| FP-100 |

130 |

100 |

32 |

1.0 |

100 |

2.0 x 0.8 |

| FP-125 |

160 |

125 |

39 |

1.5 |

50 |

1.6 x 1.2 |

| FP-150 |

189 |

150 |

47 |

2.0 |

50 |

1.8 x 1.3 |

| FP-200 |

253 |

200 |

55 |

3.5 |

40 |

2.25 x 1.1 |

- When purchasing EFLEX, it is recommended that its nominal diameter be more than 1.5 times as large as the outer diameter of the cable to be accommodated.

- The allowable bending radius should be five times or more of the EFLEX outer diameter.

- ⚠ If cables are not drawn in for a long time, the pilot wires could corrode. Replace them with plastic order wires to suit the conditions of use. When drawing in cables, replace pilot wires with order wires for the purpose

- Keep away from fire

🔸 Product features

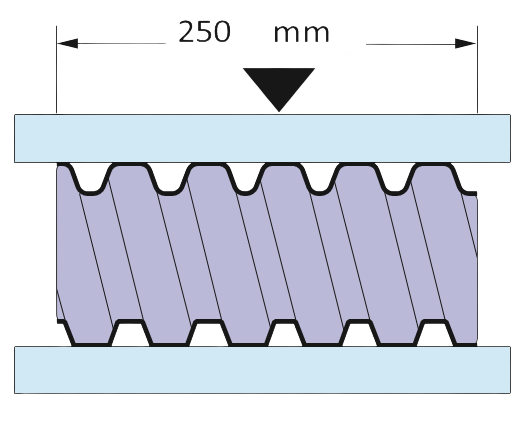

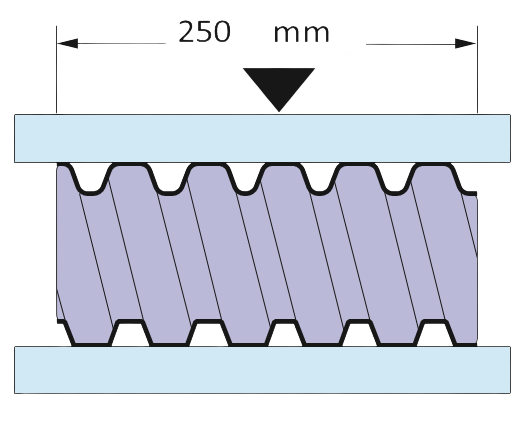

Flattened compression property

|

|

When the compression test stipulated by JIS C 3653 (Annex 1 to Installation methods of power cables buried ground) was conducted, the deformation ratio was less than 3.5% in all cases.

|

|

| Nominal diameter (mm) |

Load |

Deformation ratio

|

| N |

{kgf} |

| 30 |

373 |

38.0 |

≦ 3.5% |

| 40 |

501 |

51.1 |

≦ 3.5% |

| 50 |

612 |

62.5 |

≦ 3.5% |

| 65 |

804 |

82.0 |

≦ 3.5% |

| 80 |

969 |

98.9 |

≦ 3.5% |

| 100 |

1225 |

125.0 |

≦ 3.5% |

| 125 |

1518 |

154.9 |

≦ 3.5% |

| 150 |

1805 |

184.2 |

≦ 3.5% |

| 200 |

2412 |

246.1 |

≦ 3.5% |

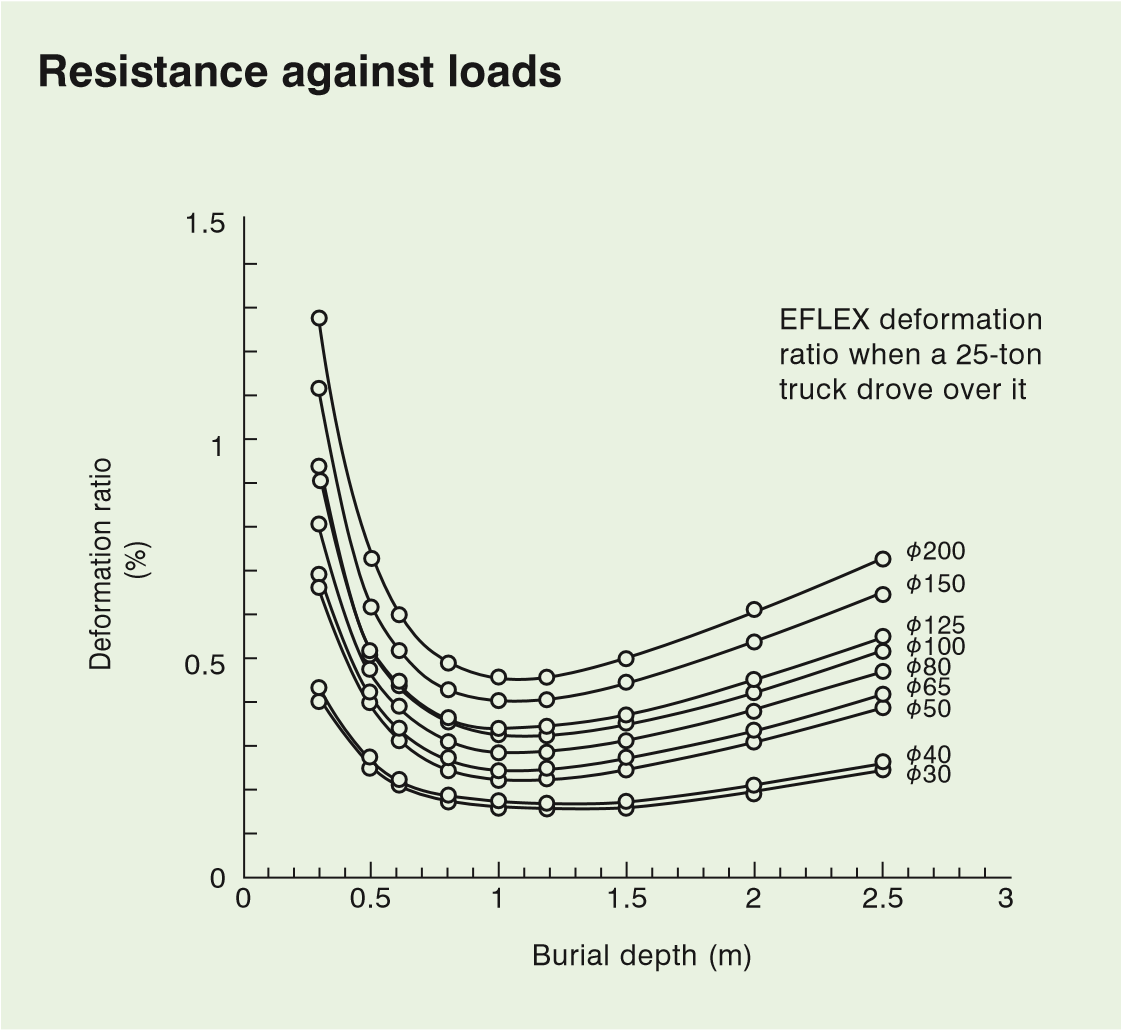

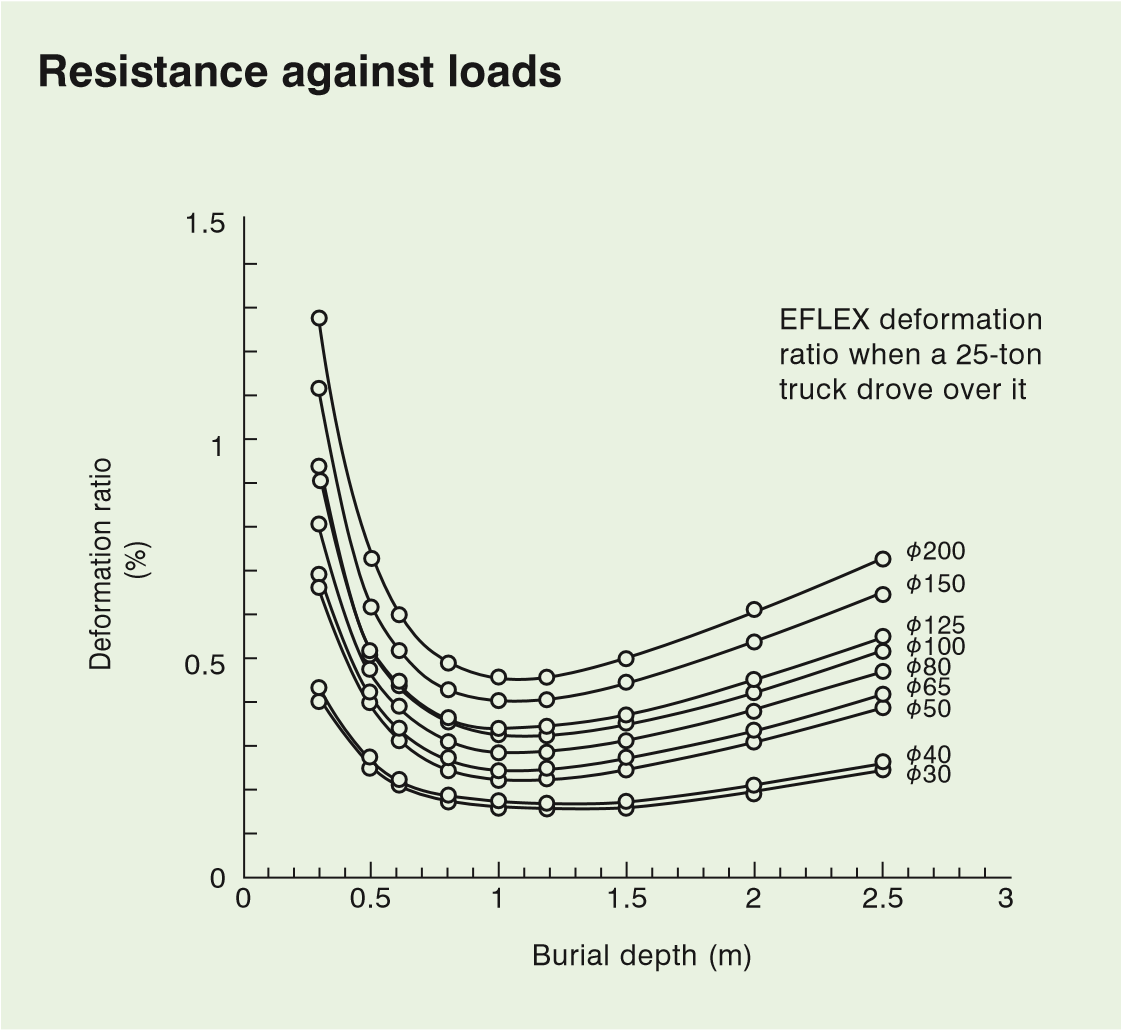

Resistance against loads

When a 25-ton truck drove over a location where EFLEX has been buried at a depth of 30 cm from the ground surface, the deformation ratio was less than 3.5%, demonstrating sufficient resistance against loads.

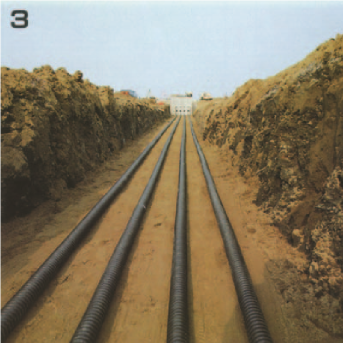

🔸 EFLEX Work Procedures

Long and easy-to-bend EFLEX saves labor and shortens work time when laying conduits.

- ⚠ Roll the girp to extend the cable.

- Make sure that cable do not wind while thay are being laid.

- Compact the ground under EFLEX, especially near the manhole.

- Pirerce with rods for tesing, to discern whether cable-laying conditions are acceptable.

- Feel free to order our Work procedure document for details.

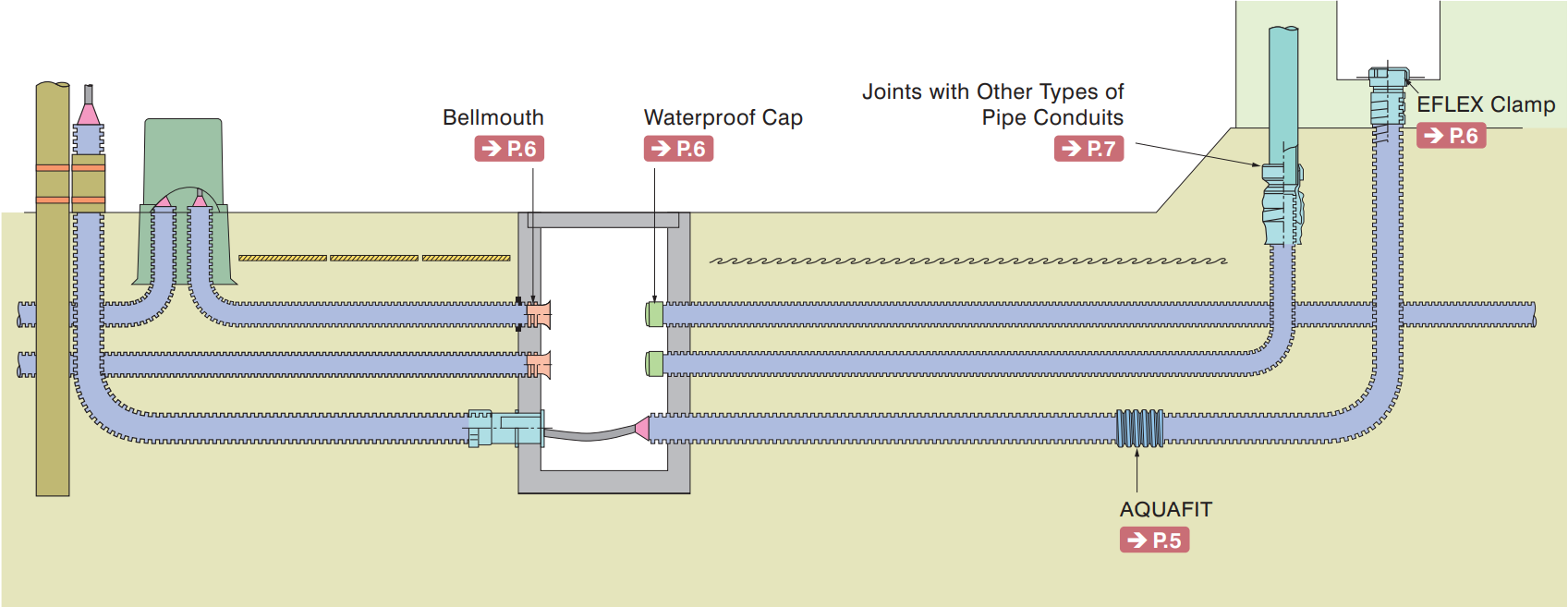

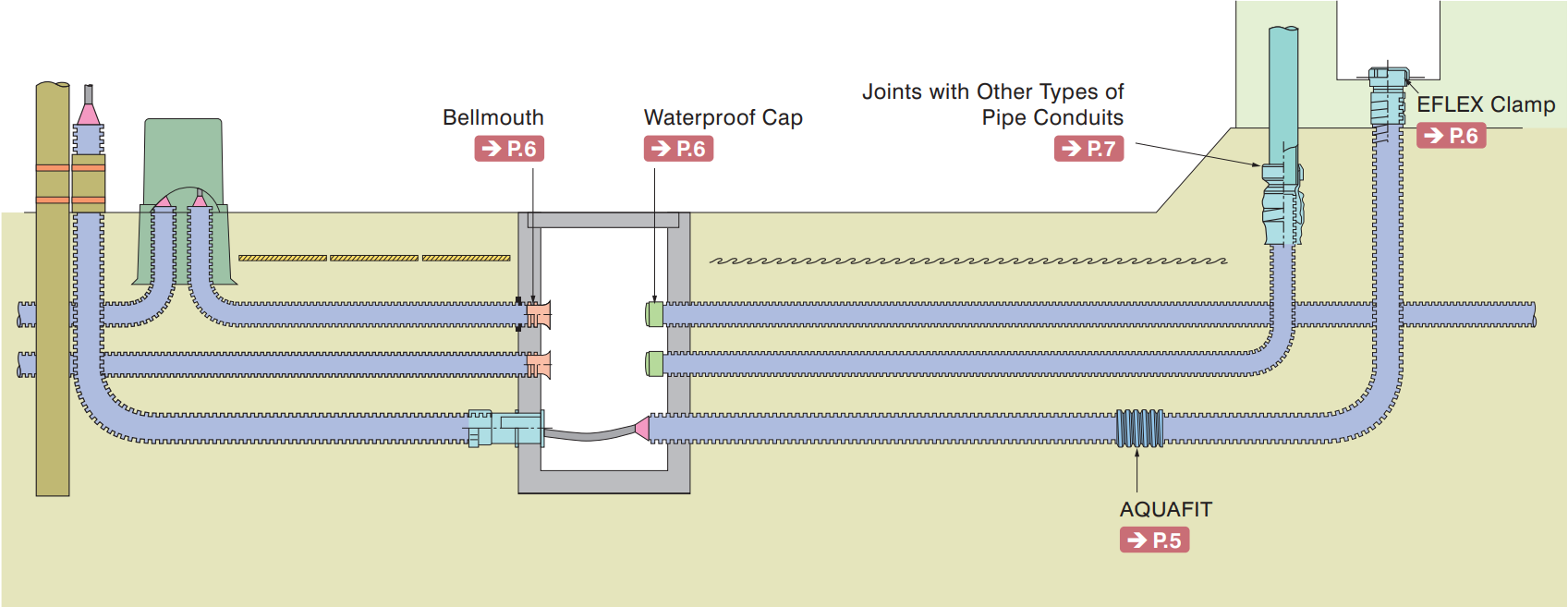

🔸 EFLEX System

Various components are combined to protect cable inside EFLEX

| |

AQUAFIT (Straight Joining Procedure for Joining EFLEX System Together)

|

FSA

.png)

.png)

| Product No. |

Outer dia. øD

(approx. in mm) |

Length L

(approx. in mm) |

| FSA-30 |

44 |

52 |

| FSA-40 |

60 |

72 |

| FSA-50 |

70 |

90 |

| FSA-65 |

90 |

115 |

| FSA-80 |

111 |

135 |

| FSA-100 |

140 |

175 |

| FSA-125 |

172 |

182 |

| FSA-150 |

201 |

190 |

| FSA-200 |

260 |

270 |

🔸 Work procedures

1. Twsit the joint at one end of EFLEX.

2. Line one end of EFLEX up with another

3. Twist the joint in 1. back so that the connecting part is centeered

* AQUAFIT of radius between ø125 and 200 can be worked more smoothly using a belted wrench and other tools. Cut the edge of EFLEX perpendicularly.

⚠ Do not remove from the bag until immediately before working, as a non-woven water-expansion cloth has been used.

Avoid storing in places exposed to high temperature and humidity or direct sunlight.

Avoid using in places where a large volume of water will penetrate the duct part.

|

|

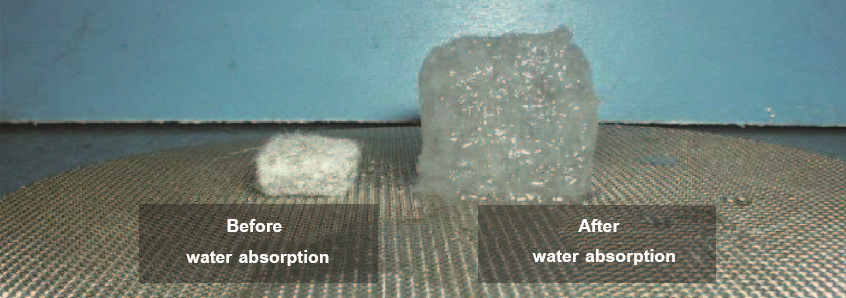

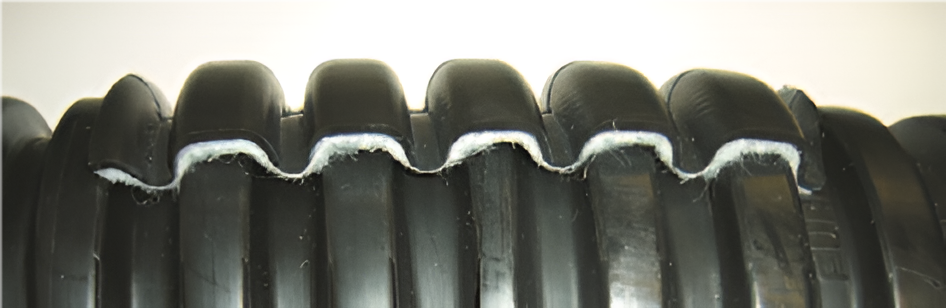

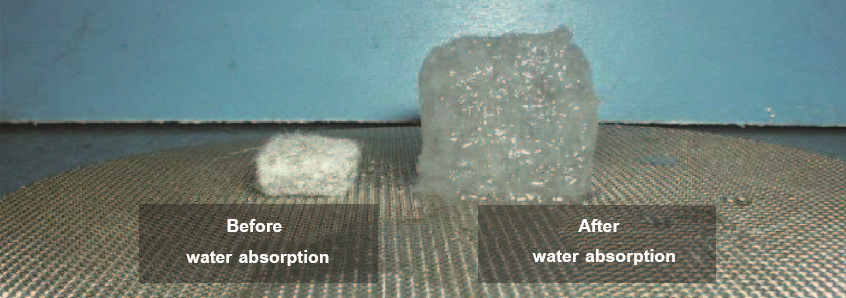

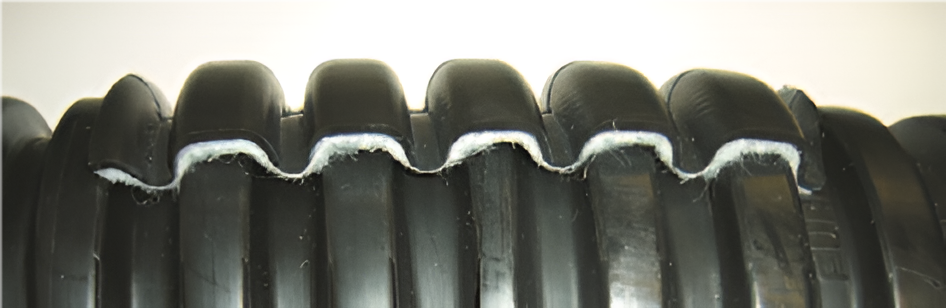

Excellent waterproofing property of non-woven water-expansion cloth

When non-woven, water-expansion cloth comes into contact with water, it expands immediately and stops wa-ter from seeping.

|

|

⏩ |

.jpg) |

|

Cross section before water absorption

|

|

Cross section after water absorption

|

|

FM

.jpg)

After EFLEX has been fixed to the man-hold, the bellmouth shouth should be attached to the end part of EFLEX to enhance the appearance and prevent cable from be-ing scratched of damaged while being pulled in. The bellmouth can be screwed easily into the EFLEX.

|

| Product No. |

Outer dia. DT

(approx. in mm) |

Inner dia. d

(approx. in mm) |

Length L

(approx. in mm) |

| FM-30 |

50 |

26 |

40 |

| FM-40 |

65 |

36 |

50 |

| FM-50 |

78 |

45 |

60 |

| FM-65 |

97 |

60 |

75 |

| FM-80 |

115 |

74 |

85 |

| FM-100 |

144 |

93 |

105 |

| FM-125 |

176 |

116 |

130 |

| FM-150 |

205 |

141 |

150 |

| FM-200 |

272 |

189 |

185 |

|

CL

|

|

If EFLEX units are fitted to a terminal box, use the EFLEX clamps aas shown in the Figure.

A hole such aas that indiacated in the Table below should be opened on the EFELX fiting plane of the terminal box to match the diameter of EFLEX used.

|

| Product No. |

Bushing

(apporx. in mm) |

Connecting tube

(apporx. in mm) |

Hole dia

(appox. in mm) |

| D1 |

L1 |

D2 |

D3 |

L2 |

| CL-30 |

51 |

13 |

50 |

41.9 |

76 |

42.7 |

| CL-40 |

77 |

18 |

73 |

59.6 |

96 |

60.4 |

| CL-50 |

88 |

18 |

90 |

75.2 |

105 |

76.0 |

| CL-65 |

101 |

18 |

104 |

87.9 |

136 |

88.7 |

| CL-80 |

117 |

22 |

116 |

100.3 |

151 |

102.7 |

| CL-100 |

132 |

24 |

135 |

113.0 |

178 |

115.4 |

| Product No. |

Collar

(apporx. in mm) |

Hold dia

(apporx. in mm) |

| L |

D |

| CL-125 |

41 |

191 |

170 |

| CL-150 |

47 |

228 |

200 |

| CL-200 |

63 |

290 |

265 |

| |

Waterproof Cap for EFLEX End |

|

FFC

.png)

|

- Kind: 9 types FFC-30, 40, 50, 65, 80, 100, 125, 150, 200

- Composiltion Waterproof cap, sealing tape, and PVC tape

|

|

Screw the water cap onto the outside of EFLEX (the amount of EFLEX protruding from a wall should match the taping). Wrap sealing around the boundary line of EFLEX and secure its end PVC tape.

|

| |

Epoxy putty (wall surface waterproofing meterial) |

|

EPOKAN (In cans)

Total weight: 3 kg

.png)

Base agent : 1.5 kg;

hardening agent: 1.5 kg

|

EPOAL

(In bags) 1 kg

Base agent : 0.25 kg x 2;

hardening agent: 0.25 kg x 2

|

|

Use when EFLEF is attached to a manhole for laying cable at a place with high groundweter level.

|

|

Epoxy putty amount used (Per location)

|

| EFLEX |

Hole diameter

on wall surface

(approx. in mm) |

Epoxy putty

amount used

(kg) |

| Product No. |

Outer diameter

(approx. in mm) |

| FP-30 |

40 |

80 |

0.5 |

| FP-40 |

54 |

100 |

0.5 |

| FP-50 |

65 |

110 |

0.5 |

| FP-65 |

85 |

130 |

1.0 |

| FP-80 |

102 |

160 |

1.0 |

| FP-100 |

130 |

180 |

1.5 |

| FP-125 |

160 |

210 |

2.0 |

| FP-150 |

189 |

260 |

4.0 |

| FP-200 |

253 |

310 |

5.5 |

| |

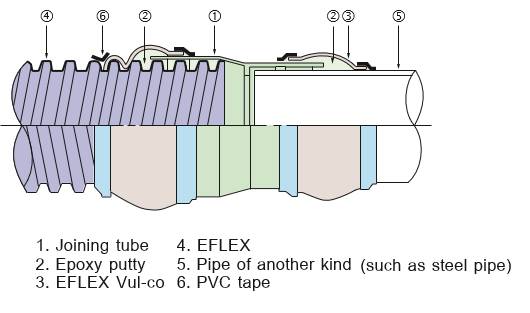

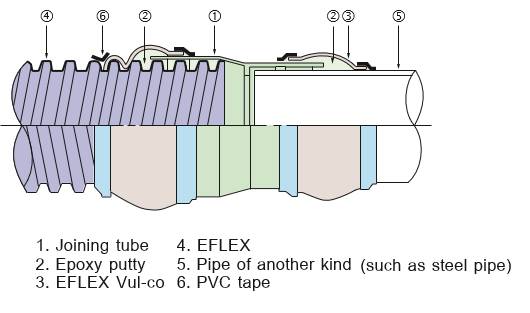

Joints with Other Typesof Pipe Conduits (Connecting EFLEX with pipes of another kind) |

- AQ-type and H-type joints for another kind pipes

.png)

⚠ Special packing is necssary for export (UN classifition 'class9' material is included in products.)

If you require a joint for connecting different types of pipes, please contact us with the sizes of the pipes.

|

Other Relevant Products

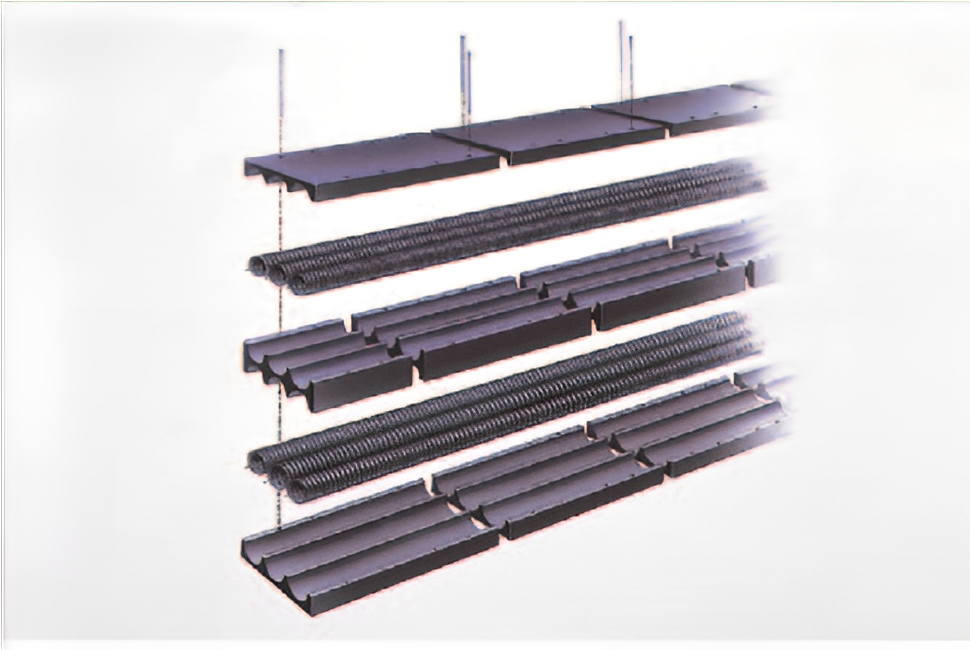

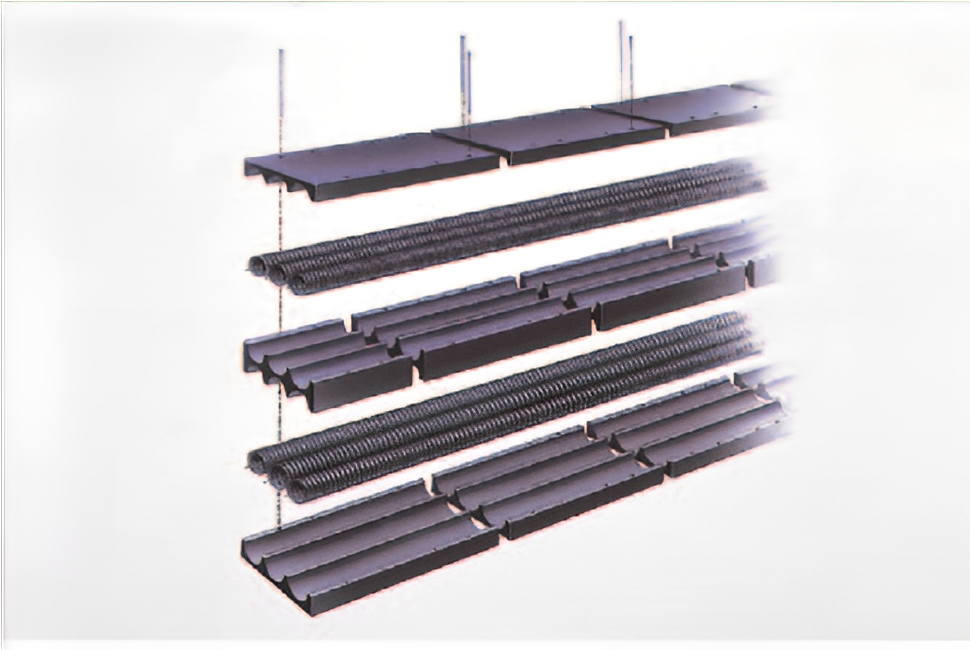

A New Multi-hole Pipe of Unit-type Pursuing Work Laborsaving and Cost Reduction.

The information box project, the so-called C·C·Box Project, is being promoted by the Ministry of Land, Infrastructure and Transport, aimed at “promotion of underground laying of electric cables” as well as “early realization of advanced information society.” To respond to such demands of the times, Furukawa Electric has developed a multi-hole pipe of synthetic resin as a cable duct material using recycled plastics. We hope the customer will make use of our materials system for underground cable laying that we have developed in pursuit of work laborsaving, shortening of work periods and cost reduction.

Thanks to Its Weight Only 25% of Concrete Trough in Addition to Its Superior Workability, Green-Trough Promises Shortening of Working Period and Reduction of Working Costs.

GREEN-TROUGH

Waste plastics from electric wire and cable sheathes that were conventionally disposed of as industrial waste are recycled to be born again as this cable protection trough. Thanks to its superior impact resistance, high resistance against salt and chemicals along with flame retardance, Green-Trough can be used for a long time with excellent stability. It also offers outstanding workability and a possible reduction in construction period due to its light weight, and reduces the exchange work of troughs thus helping to reduce industrial waste as well as to preserve resources

ท่อขาว PVC, ท่อพีวีซีสีขาว และอุปกรณ์

ท่อขาว PVC, ท่อพีวีซีสีขาว และอุปกรณ์  ท่อขาว PVC LINK, ท่อไฟพีวีซีสีขาว ท่ออโลหะ

ท่อขาว PVC LINK, ท่อไฟพีวีซีสีขาว ท่ออโลหะ  ท่อขาว Clipsal ,ท่อไฟพีวีซีสีขาว Clipsal , ท่ออโลหะ Clipsal

ท่อขาว Clipsal ,ท่อไฟพีวีซีสีขาว Clipsal , ท่ออโลหะ Clipsal  ท่อเหลืองตราช้าง, ท่อไฟพีวีซีตราช้าง, ท่ออโลหะตราช้าง

ท่อเหลืองตราช้าง, ท่อไฟพีวีซีตราช้าง, ท่ออโลหะตราช้าง  ท่อขาวตราช้าง ,ท่อพีวีซีสีขาวตราช้าง,ท่อขาว JIS standard

ท่อขาวตราช้าง ,ท่อพีวีซีสีขาวตราช้าง,ท่อขาว JIS standard  ท่อขาวตราช้าง ,ท่อพีวีซีสีขาวตราช้าง,ท่อขาว BS standard

ท่อขาวตราช้าง ,ท่อพีวีซีสีขาวตราช้าง,ท่อขาว BS standard  ท่อเอชดีพีอี HDPE, และอุปกรณ์

ท่อเอชดีพีอี HDPE, และอุปกรณ์  ท่อEFLEX และอุปกรณ์ สำหรับงานฝังดินภายนอก

ท่อEFLEX และอุปกรณ์ สำหรับงานฝังดินภายนอก  ท่อ EFLEX-FR หน่วงการเกิดไฟ และอุปกรณ์

ท่อ EFLEX-FR หน่วงการเกิดไฟ และอุปกรณ์  ท่อPFLEX และอุปกรณ์ สำหรับงานภายในอาคาร

ท่อPFLEX และอุปกรณ์ สำหรับงานภายในอาคาร

.png)

.png)

.png)

.jpg)

.jpg)

.png)

.png)

.png)